TECHNICAL INFORMATION

Quality Control procedures are well defined and thoroughly implemented.

Steel is an alloy predominantly composed of iron and carbon, with varying amounts of other elements. It’s one of the most widely used materials in engineering and construction due to its exceptional strength, versatility, and durability.

Steel's primary ingredient is iron, and its carbon content typically ranges from 0.02% to 2.14%. The carbon increases the hardness and tensile strength of the steel but decreases its ductility. The composition of steel can be adjusted by adding various alloying elements such as manganese, chromium, nickel, and molybdenum, which can enhance specific properties. These variations lead to different types of steel, including:

Carbon Steel : Composed primarily of iron and carbon, with a carbon content up to 1.5%. It's categorized into low, medium, and high carbon steels based on carbon content. Low carbon steels (0.05% to 0.3% carbon) are more ductile and easier to weld, while high carbon steels (0.6% to 1.5% carbon) are harder and used for cutting tools and springs.

Alloy Steel : Contains additional alloying elements such as chromium, nickel, and vanadium. These elements improve various properties, such as strength, toughness, and wear resistance. Stainless steel, a type of alloy steel, includes chromium (at least 10.5%) which makes it highly resistant to corrosion and staining.

Tool Steel : Specifically designed for making tools, it contains various alloying elements to improve hardness and resistance to abrasion. It’s used in manufacturing cutting tools, dies, and molds.

Structural Steel : Used in construction and engineering applications, such as beams, columns, and braces. It typically has a low carbon content but may contain additional elements like manganese to improve strength.

Steel production involves several stages:

Ironmaking : Iron ore is smelted in a blast furnace to produce molten iron. This process involves combining iron ore with coke (a carbon-rich substance) and limestone. The coke reacts with the iron ore to produce molten iron and carbon dioxide.

Steelmaking : The molten iron is refined into steel using either the Basic Oxygen Steelmaking (BOS) process or the Electric Arc Furnace (EAF) process. BOS involves blowing oxygen through the molten iron to remove impurities, while EAF uses electric arcs to melt scrap steel.

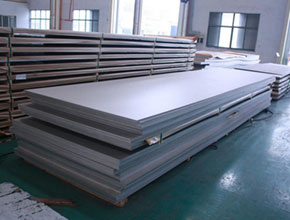

Casting and Rolling : The refined steel is cast into various shapes, such as billets, blooms, or slabs. It’s then rolled into final products like sheets, plates, or bars. Hot rolling and cold rolling processes are used depending on the desired final product.

Steel's properties include high tensile strength, ductility, and toughness, making it suitable for a broad range of applications. It’s used in construction (buildings, bridges), transportation (cars, trains), and manufacturing (machinery, tools). Steel’s adaptability to various conditions, combined with its cost-effectiveness, continues to drive its widespread use across industries.

The company has over two decade long record of servicing customers in India as well as all over the world. The company attaches significant emphasis on ensuring adherence to quality standards at all levels.

The basic thrust of the quality philosophy is summed up in the company's Quality Policy which serves as the bench mark of all functions executed by the company. Strict quality assurance system is being followed in all our departments and Total Quality Management is applied to streamline and all the procedures and practices in operation to achieve high standard of efficiency.

Why Choose Us

Top Product Best Price

Global Shipping

Wide Product Range

Petrochemical

Chemical

Refineries

Fertilizers

Oil & Gas

Construction

"Reliable, durable products; perfect for construction, never disappoints with quality or service."

"Efficient service, top-notch quality, ideal for industrial needs, consistently delivers on-time, highly recommended."

"Diverse range, expertly crafted products, tailored solutions, reliable partner, superior quality, professional service."

CONTACT PERSON

Naresh Mali | Sales & Marketing Manager

CORPORATE ADDRESS

Parmar Steel

48/50, Hingwala Building, Office No. 8, 3rd Floor, C. P. Tank Road, Mumbai - 400004, Maharashtra, India

Get Direction

CONTACT NUMBER