Submit Your Requirements For Free Estimate.

/SS Fasteners Stainless Steel Fasteners Stainless Steel Fasteners SA193 B7 Stud Bolts Industrial Fastener Manufacturer SS Hex Bolt Stainless Steel Hex Bolt Stainless Steel Bolts Stainless Steel Bolt Stainless Steel Fasteners U Bolt Clamps Ss Hex Bolt

/Gun Metal Rod MS Foundation Bolts Phosphor Bronze Rods GI Flat Bar SS 904L BOLT WITH NUT SS Square Threaded Stud

Blind Flanges MS Slip On Flange Weld Neck Flanges Plate Flanges/A105 Flange

/ Alloy Steel Flange Stainless Steel Flanges Stainless Steel Flanges

PRODUCT RANGE

-

Pipes

- Stainless Steel Erw Pipe

- SS Pipe/SS ERW Pipe/ SS Erw Tube

- A 106 Seamless Pipe

- ASTM A106 Seamless Pipes

- ASTM A106 Pipes

- Carbon Steel ASTM A106 GR A

Seamless IBR Pipes - ASTM A106 GRB Pipes

- Stainless Steel Seamless Pipe

- Seamless & Welded Stainless Steel Pipe

- Astm A106 Gr B Seamless Pipe

- ASTM A53 Pipes

- Ms Pipe Fabrication

- Spiral Welded Pipe

- Carbon Steel Seamless Pipe

- Steel Pipes

- Carbon Steel Pipe

-

Stainless Steel Pipes

- SS Seamless Bright Tube

- Stainless Steel Piping

- Stainless Steel Tube

- Stainless Steel Tubing / Pipes

- Stainless Steel Pipes

- 304 Stainless Steel Pipe

- Stainless Steel Pipe Tube

- Seamless Stainless Steel Pipes

- Stainless Steel Pipes

- Stainless Steel Welded Pipes

- Stainless Steel Pipes 309

- Stainless Steel Erw Pipe

- Stainless Steel Pipe 316

- SS Welded Polished Pipes

- Stainless Steel Pipes

- Stainless Steel Seamless Tubes

- 316L Stainless Steel Pipe

- Jindal Stainless Steel Pipes

- Stainless Steel Electro Polished Tube

- Stainless Steel Capillary Tubes

- Carbon Steel Seamless Pipes ASTM

API 5L GRADE B - Stainless Steel Pipes

- Fabricated Stainless Steel Pipe

- Stainless Steel Pipes 310

- Stainless Steel Rectangle Pipes

- Stainless Steel Square Pipes

- Threaded Pipe

- Pipe & Tubes

- Pipe Elbow

- Steel Pipe

-

Carbon Steel Pipe Fittings

- Carbon Steel Seamless Pipes

- SS Pipe Fittings

- BSP Pipe Fittings

- NPT Pipe Fittings

- BSPT Pipe Fittings

- Butt Weld Fittings

- Ms Pipe And Fittings

- Tee Pipe Fittings

- Pipe Fittings Adapters

- Gi Pipe Fittings

- Carbon Steel Pipe Fittings

- Pipe Fitting Reducers

- Reducer Pipe Fittings

- Industrial Pipe Fittings

- Carbon Steel Pipe Fitting

- BSP Pipe Fittings Dimensions

- Pipe Fitting Dimensions

- Threaded Pipe Fittings Dimensions

- Butt Weld Elbow

- Butt Weld Tee

- Carbon Steel Tees

- Forged Steel Outlet Fittings

Threadolets - Pipe Reducer/Reducer Flange

/Tee Flange - SS Eccentric Reducer

- Concentric Reducers ANSI B 16.9

- Industrial Pipe Fittings

- 45 Degree Elbow

- Welded Pipe Fittings Dimensions

- Equal Tee ANSI B 16.9

- Stainless Steel Butt Weld

Pipe Fittings - Carbon Steel WNRF Flanges

ASTM A105

-

Stainless Steel Pipe Fittings

- Stainless Steel Pipe Fitting

- SS Dairy Bend

- Stainless Steel Fitting

- Steel Pipe Fittings

- Forged Pipe Fittings

- Steel Pipe Fitting

- Ss Pipe Fittings

- Pipe Fittings,Gi Pipe Fittings,

Forge Fittings - Black Steel Pipe Fittings

- Carbon Steel Fittings

- Mild Steel Pipe Fittings

- Mild Steel Tube Fittings

- Schedule 80 Steel Pipe Fittings

- SS Pipe Bush

- SS Fittings Nuts Tees Unions

- SS Ferrule Fitting

- Forged Steel Pipe Fittings

- Forged Steel Fittings

- SS EP POLISH PIPE

-

Fittings

- Ms Pipe And Fittings

- Bsp Threaded Fittings

- Stainless Steel Fittings

- Stainless Steel Pipe Fittings

- Pipe Fittings Stainless Steel

- Stainless Steel Pipe Fitting

- Carbon Steel Fittings

- EN-8,EN9 / C-45,C55 Rolled Round Bars

- Stainless Steel Npt Threaded Fittings

- IBR Carbon Steel Pipes

- Stainless Steel Flats, Strip, Shims & Foils

- Ibr Pipe And Fittings

- Cu/Ni Fitting And Flange

- Tri Clover Fittings

- Carbon Steel Forged Fittings

- Stainless Steel Tees

- Buttweld Stub End

- Carbon Steel Reducing Tee

- Stainless Steel Dairy Fittings

- ANSI B16.5 Flanges

- 180 Degree Bends

- Weld Fittings

- Hydraulic Fittings

- Brass Fittings

-

Carbon Steel Forge Fittings

- Ss Nut And Bolt

- 90 Degree Elbow

- Stainless Steel Ball Valve

- Forged Pipe Fittings

- Butt Weld Pipe Fittings

- Carbon Steel Pipe Fitting

- Stainless Steel Forged Tee

- Stainless Steel Tube Fittings

- Concentric Reducers/ Ecc Reducer

/ Reducer - SS Eccentric Reducer

- Stainless Steel Tee

- Stainless Steel Pipe Cap

- Stainless Steel Tube Fittings

- Stainless Steel Tube Fittings

- Stainless Steel Buttweld Fittings

- Butt Weld Tee

- MS Seamless Pipe Fittings

- Long & Short Stub Ends

-

Stainless Steel Forge Fittings

- Stainless Steel Fittings

- Stainless Pipe Fittings

- Stainless Steel Threaded Pipe Fittings

- Stainless Steel Pipes Fittings

- Stainless Steel Pipe Fitting

- Hydraulic Male Fitting

- Stainless Steel Butt Weld Fitting

- Stainless Steel Compression Fittings

- Stainless Steel Hydraulic Fittings

- Stainless Steel Forged Fittings

- Stainless Steel Clamps

- Pp Compression Fittings Female Elbow

- TC End Tee

- Stainless Steel Union

-

Industrial Fasteners

- SS Fasteners/SS Nut Bolt

/SS Fasteners - Stainless Steel Fasteners

- Stainless Steel Fasteners

- SA193 B7 Stud Bolts

- Industrial Fastener Manufacturer

- SS Hex Bolt

- Stainless Steel Hex Bolt

- Stainless Steel Bolts

- Stainless Steel Bolt

- Stainless Steel Fasteners

- U Bolt Clamps

- Ss Hex Bolt

- Stainless Steel Ball Valve

- Gun Metal Gate Valve

- Aluminium Alloy Sheet

- Hastelloy Buttweld Fittings

- Gun Metal Bush

- Phosphorus Bronze Rod

- Gunmetal Bush / Gun Metal bar

/Gun Metal Rod - MS Foundation Bolts

- Phosphor Bronze Rods

- GI Flat Bar

- SS 904L BOLT WITH NUT

- SS Square Threaded Stud

- High Tensile Fasteners

- Industrial Bolts/Cs Bolt/Hex Bolt

- SA193 B16 Stud Bolts

- B7 Stud Bolts

- Hex Head Bolts

- Heavy Hex Nut

- Dual Plate Check Valves

- Monel 400 Flange

- Gi Strip For Earthing

- Aluminium Alloy Sheet 6082 (T6)

- Aluminum Alloy 5083

- Hastelloy C276 Seamless Pipe

- Stainless Steel Threaded Rod

- Hastelloy C22 Fasteners

- Super Duplex Steel Round Bar

- Duplex 2205 Stainless Steel Rods

- Duplex Steel Round Bar

- Aluminium Bronze Rod

- Hastelloy C276 Pipes

- Hastelloy C276 Sheets

- Hastelloy C276 Rods

- Inconel 600 Flanges

- Titanium Flanges/Monnel Flange

/Wnrf Flange

- SS Fasteners/SS Nut Bolt

-

Flange

- Carbon Steel Flanges

- Stainless Steel Flanges

- Double Studded Adapter Flange

- Stainless Steel Flanges

- Alloy Steel Flanges

- Stainless Steel Blind Flange

- Carbon Steel Flanges

- Stainless Steel Flanges

- Stainless Steel Flanges

- Mild Steel Flanges

- Ms Flange And Blind

- MS WNRF Flange

- MS Collar Flange

- Carbon Steel Plate Flange

- ASTM A105 Flange

- Carbon Steel Flange

- CS Weld Neck Flange

- CS Collar Flange

- CS A105 Flange

- Carbon Steel Is 2062 Flange

- CS SWRF Flange

- Carbon Steel Weld Neck Flange

- ANSI B 16.5 Class 300 lb

Weld Neck Flanges - Export Flanges With Packing

- Pipe Fittings Flanges

- Flange Pipe Fittings

- Stainless Steel Pipe Flange

- MS Socket Weld Flanges

- MS Flanges/SORF Flange/BLRF Flange

- Flange Collar

-

Carbon Steel Flanges

- Blind And SORF Flanges

- Ms Collar Flange

- Steel Flanges

- Weld Neck Rtj Flange

- Forged Steel Flanges

- Slip On Flange Sorf

- Stainless Steel Wnrf Flange

- Forged Steel Flange

- Stainless Steel Flange

- Stainless Steel Blind Flanges

- ANSI B 16.5 Class 150 lb

Blind Flanges - MS Slip On Flange

- Weld Neck Flanges

- Plate Flanges/A105 Flange

/ Alloy Steel Flange - Stainless Steel Flanges

- Stainless Steel Flanges

- Carbon Steel Plates

- SS WRNF Flanges With Nut Bolt

- Carbon Steel Flange

- Ms Collar Flange

- Stainless Steel Reducing Flange

- ASTM A105 Flanges

- Din Standard Flanges

- Orifice Flanges/ SS SWRF

Flange/ LJFF - Threaded Flanges/Npt Flange

/Collar Flange - Screwed Flanges/ Flange

Adopter/Flange Bolt - Long Weld Neck Flanges

- Reducing Flanges/SORF

Flange/ BLRF Flange

-

Stainless Steel Flanges

- Stainless Steel Sorf Flange

- Stainless Steel Flanges

- Alloy Steel Flanges

- Slip On Flanges

- Stainless Steel Flanges

- Weld Neck Flange

- Lap Joint Flanges

- Stainless Steel Orifice Flange

- Stainless Steel Drawing Flange

- Ansi B 16.5 Ms Flanges Class 150

- Flanges Asme Ansi B 16.47

- Slip On Flanges

- Pipe Fittings Flanges

- Carbon Steel Elbows

- Stainless Steel Screwed Threaded Flange

- Weld Neck RF Flanges

- Spectacle Blind Flange

- Lined Reducing Flange

- Ring Joint Flanges

- Stainless Steel Threaded Flange

-

Stainless Steel Sheets

- Stainless Steel Sheet 310

- Stainless Steel Sheet 304

- Stainless Steel Sheet 202

- Stainless Steel Sheets 430

- Stainless Steel Sheet 316L

- Stainless Steel 317L Sheets

- 300 Series Stainless Sheets

- 200 Series Stainless Steel Sheet

- Carbon Steel Rings

- Stainless Steel Sheet 304L

- Stainless Steel 904L Sheets

- SS 304/304L/316/316L/310 COIL

- Stainless Steel Washers

- Sheets Plates and Coils

- EN 8 Steels

- Seel Products

- Stainless Steel Angle

- Stainless Steel Circles

- Coupling

- Industrial

- Wear Steel Plate

- Boiler Plates SA 516 GR.70

-

Stainless Steel Round Bars

- Stainless Steel Round Bar

- S.S Round Bar & Flat Bar

- Stainless Steel Bar

- Stainless Steel Round Bar

- 303 Stainless Steel Round Bars

- Stainless Steel Round Bars 316L

- Stainless Steel Round Bars 317L

- Stainless Steel Round Bars 904L

- Stainless Steel Round Bars

- En 1a Round Bar

- Stainless Steel Rod

- Stainless Steel Round Bars 304

- 17-4 PH Stainless Steel Round Bars

- Stainless Steel Round Bars 410

- Stainless Steel Bright Bar

- Stainless Steel 420 Round Bar

- Steel Supplies

- New Items

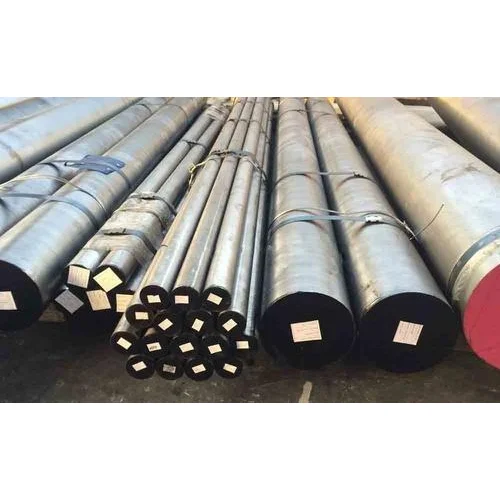

EN 8 Series Steel

Rs 52 / Kg

| Usage/Application | Construction |

| Material Grade | EN8/EN9/EN19/EN24 |

| Application | Pharmaceutical / Chemical Industry, Automobile Industry, Construction |

| Diameter | 10MMDIA TO 300MMDIA |

| Length | 6MTR |

| Shape | Round |

| Material | Stainless Steel |

EN8 also know as 080M40. Unalloyed medium carbon steel. EN8 is a medium strength steel, good tensile strength. Suitable for shafts, stressed pins, studs, keys etc. AISI 1040.

Available as normalized or rolled. EN8 is supplied as round drawn/turned, round hot rolled, hexagon, square, flats and plate.

EN8 is usually supplied untreated but can be supplied to order in the normalized or finally heat treated (quenched and tempered to ”Q” or “R”properties for limiting ruling sections up to 63mm), which is adequate for a wide range of applications. Please refer to our selection guide for comparisons.

EN8 is a very popular grade of through-hardening medium carbon steel, which is readily machinable in any condition. (Refer to our machinability guide). EN8 is suitable for the manufacture of parts such as general-purpose axles and shafts, gears, bolts and studs. It can be further surface-hardened typically to 50-55 HRC by induction processes, producing components with enhanced wear resistance. For such applications the use of EN8D (080A42) is advisable. It is also available in a free-machining version, EN8M (212A42)

EN8 in its heat treated forms possesses good homogenous metallurgical structures, giving consistent machining properties.

Chemical composition

| Element | Min | Max |

| Carbon, C | 0.35 | 0.45% |

| Manganese, Mn | 0.60 | 1.0% |

| Silicon, Si | 0.5 | 0.35% |

| Sulphur | -.-- | 0.6 |

| Phosphorus | -.-- | 0.6 |

Heat Treatment

● EN8 or 080m40 can be tempered at a heat of between 550°C to 660°C (1022°F-1220°F), heating for about 1 hour for every inch of thickness, then cool in oil or water.

● Normalizing of EN8 bright mild steel takes place at 830-860°C (1526°F-1580°F) then it is cooled in air. Welding

● Modern EN8 bright mild steel contains a lot less carbon then it uses to, this mean that it is possible to weld pieces up to 18mm thick without preheating using MIG wire (SG2) or a 7018 electrode.

● Over 18mm would require a pre-heat of 100°C (212°F) in order to prevent cracking. Flame Cut Profiles A hard edge can occur when flame cutting EN8 plate, therefore this grade is commonly normalized after flame cutting. EN8 flame cut profiles can be supplied Lumsden ground or precision ground. Ground Flat Stock Precision ground flat stock / gauge plate can be produced using EN8 steel. Subject to size suitability and availability of raw material pieces can be produced in approximately 2 to 3 weeks. Standard and non-standard sizes are available. Applications EN8 is widely used for many general engineering applications. Typical applications include shafts, studs, bolts, connecting rods, screws, rollers. Forging Preheat the steel carefully, and then raise temperature to 1050°C for forging. Do not forge below 850°C. After forging cool slowly, preferably in a furnace. Annealing Heat slowly to 680-710°C, soak well. Cool slowly in the furnace. Hardening Heat the component slowly to 820-860°C and allow it to be heated through. Quench in oil or water. Tempering Temper the EN8 component immediately after quenching whilst tools are still hand warm. Re-heat the EN8 component to the tempering temperature then soak for one hour per 25 millimeter of total thickness (2 hours minimum) Cool in air. Welding We recommend you contact your welding consumables supplier who should provide you full assistance and information on welding EN8 steel.

EXPLORE MORE PRODUCTS

We Shine For Premier Quality Product

The company has over two decade long record of servicing customers in India as well as all over the world. The company attaches significant emphasis on ensuring adherence to quality standards at all levels.

The basic thrust of the quality philosophy is summed up in the company's Quality Policy which serves as the bench mark of all functions executed by the company. Strict quality assurance system is being followed in all our departments and Total Quality Management is applied to streamline and all the procedures and practices in operation to achieve high standard of efficiency.

Why Choose Us

Top Product Best Price

Global Shipping

Wide Product Range

Industrial Application Of

Our Product

Petrochemical

Chemical

Refineries

Fertilizers

Oil & Gas

Construction

Ratings & Reviews

Rajesh Dave

"Reliable, durable products; perfect for construction, never disappoints with quality or service."

Akash Suman

"Efficient service, top-notch quality, ideal for industrial needs, consistently delivers on-time, highly recommended."

Arnab Das

"Diverse range, expertly crafted products, tailored solutions, reliable partner, superior quality, professional service."

Parmar Steel

CONTACT PERSON

Naresh Mali | Sales & Marketing Manager

CORPORATE ADDRESS

Parmar Steel

48/50, Hingwala Building, Office No. 8, 3rd Floor, C. P. Tank Road, Mumbai - 400004, Maharashtra, India

Get Direction

CONTACT NUMBER

Contact Us

PARMAR

STEEL

Empowering Construction with Steel Excellence.

Copyright © 2024 All Rights Reserved